About the Division

The Design and Development Centre in National Coir Research and Management Institute (NCRMI) is equipped with an art in-house machine shop & design centre to address all R&D mechanical project needs. The approach allows the institute to take on a single point of accountability, allowing for improved control over the manufacturing process and a shorter total lead time for the demand. The goal of the centre is to develop and test innovative coir machines as well as technology transfer. The design and development centre act as a one-stop shop for all product design and development activities for the coir industry as a destination for designing and prototyping.

Mobile Tender Coconut Crusher - TCM-700-MS1

The Tender Coconut Crusher used for the processing of consumed tender coconut husks, transforming them into crushed form for versatile applications, particularly in soil conditioning. The Mobile Tender Coconut Crusher, connected to a tractor for convenient transport, operates with a powerful 20 HP PTO shaft drive, eliminating the need for separate electricity.

Applications

Soil Conditioner, Seedling Filler Material, Agricultural Mulching, Bio-Char Manufacturing, Charcoal Block Manufacturing

Features

52 Jaw Blade Crusher, Robust Frame, PTO Direct Drive, Manual Hydraulic Lifting, Feed Hopper, Easy Cleanable, Easily Towed, Suitable for Small Spaces, Machine remains elevated during transport, Centrifugal Hammering Method, Exceptional Crushing Capability for Small- & Large-Scale Projects, Adjustable Legs for Vibration Free Operation.

Technical data

| Processing Speed | 4000-4800 husks per day |

| Feed Height | 130 CM |

| Unladen weight | 650 KG |

| Hopper width | 350 MM |

| Product Height | 100 CM |

| Product width | 100 CM |

| Product length | 090 CM(Without tractor) |

| Rated Power | 020 HP |

| Ground clearance | 470 MM (while transporting) |

Low Cost Power Loom

Low-cost power loom is developed for weaving coir geotextiles and mattings. This innovation streamlines the coir industry, offering increased efficiency, reduced labor, and improved product quality in weaving sector such as Geotextile and other Mattings.

Key Advantages

- Automation boosts productivity, enabling larger quantities in shorter time frames.

- Accessible to small-scale weavers with limited technical expertise.

- Comprehensive training programs ensure effective operation and maintenance.

- Supports eco-friendly practices using natural coir fibers.

- Enables efficient utilization of renewable resources.

Key Features

- Automated Weaving Mechanism

- Easy-to-Use Interface

- Maintenance and Safety

Technical Specifications

- Electrically operated Power Loom for various GSM Coir geotextiles and Coir mattings.

- Sturdy frame for stability, compact design for small setups.

- Sturdy warp beam with adjustable tension for proper yarn tensioning.

- Shuttle-based mechanism for efficient weaving.

- Auto-stop feature.

- Weaving speed: 1.5 Sec/weft.

- Rigid beat-up mechanism ensures tight weave control.

- Motorized mechanism winds woven coir matting onto a roll.

- Variable speed control, accommodating operator requirements.

- Coir Geo Textiles: 200 running meters; Width: 0.7 m - 2.1 m.

- Coir mattings (SK1): 90 running meters; Width: 0.7 m - 2.1 m.

- 5 HP for the main motor, 0.5 HP for the take-up mechanism.

- Power required: 440V 3 Phase AC.

Pneumatic Loom

The designed machine specializes in weaving Geo-Textile Matting with various GSM (Grams per Square Meter) sizes, and its key operations are powered by pneumatic cylinders. This loom boasts an impressive production capacity, capable of weaving 100 meters of GeoTextile Matting with a GSM of 900 per 8 hours. This high productivity makes it a valuable asset for manufacturers seeking efficient and consistent production of Geo-Textile Matting in the specified weight category. The utilization of pneumatic cylinders in the machine's operations adds precision and reliability to the weaving process, contributing to the overall efficiency and quality of the final product.

Specifications

| Production capacity | 100 M (Geo Textile Mat 900GSM) per 8 hrs |

| Width of Geo textile | 2.10 Mtr |

| Length of Geo textile | as per requirement |

| Weaving speed | 3 sec/weft |

| Production capacity | 1200 weft per hour |

| Machine Footprint | 8M x 4M x 1.7 M |

Requirements

- Air Supply (10 Bar)/ 415 V AC Three Phase power supply for compressor

- Power supply 230V AC single phase for PLC

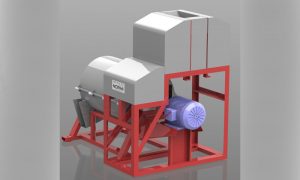

Fiber Extraction Machine

The machine is designed to extract coir fiber from both green and dry coconut husks, employing the assistance of a Crusher Unit. This innovative system facilitates the efficient separation of coir fibers from coconut husks, allowing for versatile processing of husks in different states.

Key Features

- Crusher Unit Integration: The Crusher Unit plays a pivotal role in breaking down coconut husks, facilitating the extraction of coir fibers. Efficient crushing ensures the release of fibers from the husks.

- Optimized Fiber Extraction: The design focuses on maximizing the extraction of coir fibers, ensuring a high yield of quality fibers from each husk.

- Advantages: Efficiency in Husk Processing.

- Versatility in Raw Material:

- Quality Fiber Output.

- Streamlined Production.

- Increased Productivity.

Specifications

| Processing Capacity | 6000 Coconut Husks Per Day of 8 Hrs |

| Production Capacity | 480 Kg of Fibre Per Day of 8 hrs |

| Motor Power | 10 HP, 440V 3 Phase AC |

| Machine Footprint | 2M x 1M x 1.3 M |

The development of fully automatic creel mat loom

The research program involves the development of a cost effective Creel Mat Power Loom for producing creel mat/mattings having productivity not less than 65 picks per minute. The machine will be affordable to medium scale coir product manufactures.

Development of a high tech coir yarn spinning machine

The design and development centre in NCRMI is developing a core-less coir yarn spinning machine having capacity of 1500-200 kg of coir yarn per 8hr for spinning of all varieties of coir yarn in the industry.

Development of a multi head spinning machine

This is an ongoing research project aimed to successfully develop an efficient multi head automatic spinning machine having a production capacity of 80/1200 kg per 8 hrs of shift.

The development of tender coconut husk crushing machine

After successful development of Mobile Tender Coconut Crusher, NCRMI design and development division is proposed to develop a stationery Tender Coconut Crushing Unit devising higher production capacity than the mobile unit. The fabrication of the machine is undergoing in NCRMI.

Design and fabrication of pyrolysis unit for the conversion of coconut palm biomass residues to biochar for soil amendment.

This project aims to convert the pulverized coco biomass into biochar by designing, fabricating and developing a system for pyrolysis in-house at NCRMI. Furthermore, the biochar thus produced shall be chemically evaluated to study the efficacy of the biochar as soil amendment, and thereon field trial studies are also proposed.

Facilities in Design Centre

The Design Centre is fully equipped with high end systems with 3D design Software and 3D printer for instant Prototyping.

Facilities in Engineering Workshop

The engineering workshop is outfitted with both traditional and cutting-edge CNC machines of reputed manufacturers. These machines are capable of working with a wide range of component sizes. The NCRMI team of experienced engineers and machinists together with a well-equipped tool room support the facility to attain higher levels of excellence.

Major Machineries

- Conventional Lathe

- Universal Milling Machine

- Radial Drilling Machine

- Surface Grinding Machine

- Cylindrical Grinding Machine

- Tool Grinding Machine

- Hydraulic Press

- Hydraulic Press Brake

- Hydraulic Shearing Machine

- CNC Vertical Machining Centre

- CNC Turning Centre

- Hydraulic Ironworker

Road Show of Mini DF developed by NCRMI

NCRMI has conducted a road show in the month of August 2010 for publicizing its newly developed Mini DF machine throughout the state of Kerala. The DF machine was displayed and its working was also demonstrated at prime areas throughout the road show. Apart from prime spots the mini DF machine was also demonstrated at various coir cooperative societies. The road show attracted huge demand for the mini DF machine launched by NCRMI.

- Sri Abhishek C, Scientist S3

- Sri Ajith S V, Technical Officer (Mechanical)